|

Nope. Well, not necessarily.

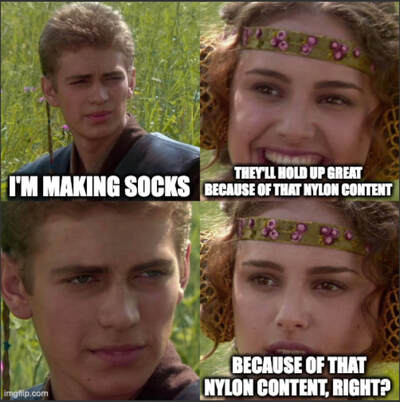

Let’s back it up a step, though. “Fingering-weight.” Where does that term even come from? The most-often cited etymology is from the French phrase “fin graine,” meaning “fine-grained.” As a French speaker… well… that gets some serious side-eye from me. The word order is wrong, and it doesn’t appear that “graine” is a word that has applied to wool or yarn*. Additionally, as Norman at the Nimble Needles blog points out, yarns in Europe are sold by the size of needle you would use with them and not by general category. Norman did some excellent detective work and tracked down what he believes to be the origin of the term - in the Scottish National Dictionary, a type of woolen cloth is labeled “fingering,” which the dictionary proposes comes from a spinning technique that, by that time, had been lost in terms of its relationship to the creation of the yarn used in the fabric. (Seriously. Go read Norman’s post. It’s FASCINATING.) Fingering-weight yarn, according to the Craft Yarn Council standards, averages a single crochet gauge of 21-32 stitches in 10 cm / 4” and a stockinette gauge of 27-32 stitches in 10 cm / 4”. That’s an incredibly wide range (especially for crochet). The “put-up” - how many yards there are in a standard skein or hank - can range from 366 meters / 400 yards in 100 grams to 425 meters / 465 yards in 100 grams. That’s a 14% difference in yarn thickness between the ends of the range! Why, for so many people, does “fingering-weight” then automatically equal “sock yarn”? Smaller stitches tend to both feel better on the foot and wear better over time in high-friction contexts - so it makes sense to make socks out of finer yarn. And why is THAT, you might ask? The soles of our feet are incredibly sensitive. Think of how fine some of the grit is that you find in your shoe after a walk on the beach, and how disproportionately annoying it is to figure out what’s bugging you in your shoe before you sit down and tap it on a bench or a curb.. The purl bumps on the inside of a sock are more uneven than the knit side, so if you have larger yarn in a sock, everything about those purl bumps is going to feel unusually irritating. (There is a solution to this - called a “princess sole” - which has you purl the stitches on the sole of the sock so that the smooth knit-stitch side is directly against your foot.) Using large yarn means your stitches are larger, and more of each stitch is going to be exposed to abrasion and wear away more quickly than the small stitches. So if fingering-weight yarn isn’t automatically sock yarn, then what gives? What IS sock yarn? That’s an excellent question and one that will kind of depend on who you ask. At the shop, I maintain that sock yarn has two very important characteristics - 1, it’s tightly plied. 2, it contains some sort of fiber that is going to help combat destructive abrasion. Tightly plied yarn is going to expose less of each strand of the yarn (called a single when we’re talking about yarn construction), and it’s going to be springy - and therefore able to stretch and give in response to the movement of your foot. The second fiber is going to strengthen the yarn - it’s often nylon, but sometimes silk or mohair are used instead. There are several yarns on the market in DK-weight and worsted-weight that are specifically pitched as sock yarns because they meet these two criteria, and I agree with that classification. The takeaway - there are several different positions on this, but I’m going to come down on the side of saying that it’s only sock yarn if it meets specific conditions that will help it resist abrasion and stretch to help with the negative ease that most socks require. Fingering weight can be all over the place in terms of fiber content and yarn construction, but if it doesn’t have a strengthening agent or tight spin, I’m not going to recommend it for durable socks - and therefore it’s not a true sock yarn. *I need to absolutely confirm this with my big French dictionary, but it is currently behind about 35 kg / 80 lbs of boxes in our home library - the online version of this same dictionary has definitions from the 17th century, which do not include fabric / fiber grain among its definitions, either.

0 Comments

One of the most frequent requests we get for assistance in our shop is to help people find the right yarn for their project. Either the pattern calls for a very specific yarn and doesn’t give information on equivalents, or the pattern calls for a specific “weight”of yarn but assumes the crafter knows exactly what to ask for. If you’ve ever seen a pattern that calls for “fingering-weight yarn,” or “baby yarn,” or “a #2 yarn”, you’ve dealt with yarn weight.

This is a vast and complex topic, but let’s break it down into some basic bullet points this week. 1 - “Yarn weight” is kind of* another way of saying “yarn size.” (*it’s complicated) When you search for yarn in a certain weight, you’re looking for a yarn that, due to its general ratio of yards to ounces (or meters to grams), is likely to act the way you expect it to in a given pattern. This is a bit of an overgeneralization, as the way a yarn is spun can cause it to behave like other yarns in a given “weight class” but look like a very different yarn weight on the shelf. 2 - There are at least 3 ways that people assign a weight to yarns. You’ll see yarn weight assigned solely based on the ratio of yards to ounces / meters to grams, or by stitches per inch, or by wraps per inch. The first two methods are the most common; wraps per inch (or WPI) tend to be more used by weavers and spinners. 3 - Not everyone agrees on the “correct” way to assign a yarn weight classification. The more information you have on a given yarn, the more of an understanding you have on how that yarn is likely to behave in a given pattern, or on a given hook or needle size. Most of our commercial yarns at the shop have the ratio on their labels as well as the stitches per inch measurement. In the shop, I tend to rely pretty heavily on the ratio method to assign yarns their spot in the shop since the shop is laid out in yarn-weight order; however, I also take into account technical knowledge about how some of our yarn options are spun when I’m making that decision. (More about that in a later post!) When I’m working with customers to decide on which yarn is right for their pattern, the ratio method gives me a ballpark idea of where to look for a good match; the washed, blocked swatch will give us the final answer with the most accuracy. There’s a group called the Craft Yarn Council that has a chart with all kinds of information on how yarns in the same “weight class” can be measured - you can get it for free at craftyarncouncil.com. 4 - Crocheters and knitters often use different scales to describe the same yarns. Crocheters in the US tend to use a numerical scale that runs from 0-7 to classify yarns. Knitters in the US tend to use a word-based scale (cobweb, lace, fingering, sport/baby, DK, worsted, aran, bulky, super-bulky, jumbo) to classify yarns. They can be used interchangeably to describe the exact same yarns, just in different terms. 5 - Even if a yarn is labeled the same weight as what you need for a pattern, not all yarns in the same yarn weight are equal! Yarn weight categories cover a LOT of ground. Just because something is classified as a “worsted-weight” or #4 yarn doesn’t mean it will knit up exactly like the #4 / worsted-weight yarn that the designer used - especially if the designer didn’t specify which yarn they used! A yarn that has alpaca content and 175 yards per 100 grams isn’t generally going to behave the same way as a mostly acrylic yarn that has 230 yards per 100 grams, even if they’re both called worsted-weight yarns by the yarn company or the yarn shop. This is where gauge swatches come into play. Pattern yarn recommendations are ultimately guidelines. Even if you use exactly the same yarn and hook/needle size as the designer, you might not be able to get the same gauge they published in the pattern because you crochet/knit more loosely or tightly than they do. So there you go - watch this space over the next few weeks for more posts about specific aspects of yarn weight. We'll post a new article each Tuesday and let you know on our social media feeds (Instagram, Facebook, and Threads). |

AuthorLindsey Spoor is the owner of Stilly River Yarns in Stanwood, WA. Archives

April 2024

Categories |

Reach out! |

Come visit us at our brick-and-mortar shop in Stanwood!

NEW LOCATION STARTING JULY 16, 2024:

7104 265th St. NW Suite 120 Stanwood, WA 98292 Shop phone: (360) 631-5801 Email: [email protected] Text: (515) 833-0689 |

|

|

Proudly powered by Weebly

Stilly River Yarns LLC

Copyright © 2024

Copyright © 2024

RSS Feed

RSS Feed